Torque Motors marked a revolution in the Electric Motor World.

Many aspects, concepts and possibilities have been redefined by this game changer technology.

As every large scale transition, it is not always easy to fully understand the advantages and learn how to apply them in the best way.

Let’s dive with us in the torque motor technlogy analysis through a common questions review.

Many improvements has been brought by torque motors regarding fast and precise positioning, quite and smooth movements, high torque, easy of design and integration, efficiency, energy and cooling demand

Because this kind of electric motor enables higher torque value, especially at low speed.

So the keyword “torque” perfectly fits this kind of motors, representing the most improved performance aspect.

Torque motors are named gearless motors as well, due to the absence of gearbox.

Torque Motors are generally integrated in systems where torque is directly transmitted to the load, so “direct drive” term indicates this direct transmission, that does not require gearbox or other mechanical coupling.

“DD” motors is a common abbreviation for Direct Drive Motors.

Many improvements has been brought by torque motors regarding fast and precise positioning, quite and smooth movements, high torque, easy of design and integration, efficiency, energy and cooling demand

Maximum Speed is for sure the main limit respect traditional servo motors.

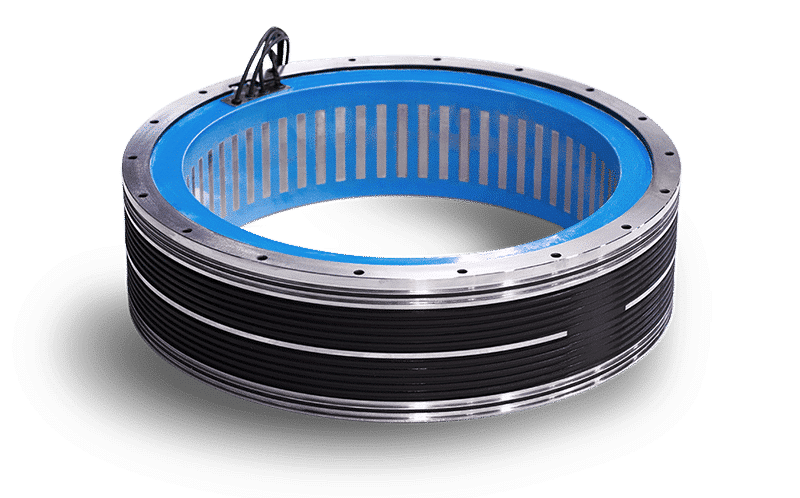

Shape: torque motors have typically a large diameter toroidal shape, respect to the minor diameter long axis form factor of servo motors.

Performance: torque motors allows more torque and precision, especially at low speed; servo motors are normally better in speed performance

Efficiency: torque motors definitly win in efficiency, due to minor mechanical loss, low speed, energy and cooling demands.

Energy and Environment: torque motors are definitely the most eco-friendly choice, considering the less energy demand, minor noise, maintenance, and total number of parts.

All that applications that require high torque ad low speed, or where smoothness precision or compactness are key aspects.

Nowadays, large and growing application of torque motors is made in the following fields:

Direct Drive is still a growing and expanding market and will represent for sure the future of electric motors technology and market.

The Frameless “ring” configuration is a very common for torque motor implementations.

Frameless design allows lightweight and space saving solution, with easier magnets or windings replacement, due to the absence of housing.

Anyway, frameless design it is not mandatory: it is just one of the several flexibility and innovative advantages of torque motors.

So, the motor housing is still possible in direct drive technology applications.

In much cases it is better to let the Torque Motor Manufacturer to provide the housing, due to its capability and experience handling the housing tollerances and possible issues.

Generally torque motors does not need gears thanks to the ability to generate high torque at low speed.