Imagine a World where power, precision and simplicity merge into a single revolutionary motion solution: Torque Motors.

The revolutionary e-motor concept that eliminates gears and coupling, thanks to direct transmission, ensuring immediate response and unparalleled precision. Mechanical components, moving parts, friction, failures, noise, energy consumption are strongly reduced as well.

Torque motors excel in applications requiring fast and smooth movements, extremely accurate controls, representing the the future of electric motion industry.

Ready to discover how this cutting-edge technology brings performance, efficiency and reliability to new levels?

Torque Motors, also know as Direct Drive Motors, directly applies torque to the load, without coupling like gears, belts or chains. It provides to the most accurate, compact, efficient electric motion solution today available on the market.

Direct Drive Technology results in motion control solutions with

On the performance side, torque motors lead to high rigidity, low cogging and zero backslash systems, with high torque and high speed and precision capability.

Direct Drive Motors are named “torque motors” as well, because they lead high torque values comparing to traditional electric servo motors.

Thanks to high specific torque density, frameless torque motors are very suitable for space saving solutions, ideal for small building volumes, as for high volume applications.

Direct Drive Motors offer to machine builders unparalleled possibilities for space optimization and better design of supports cooling system and joints.

Explore Real Applications of

Torque Motors Tecnology

by Phase Motion Control

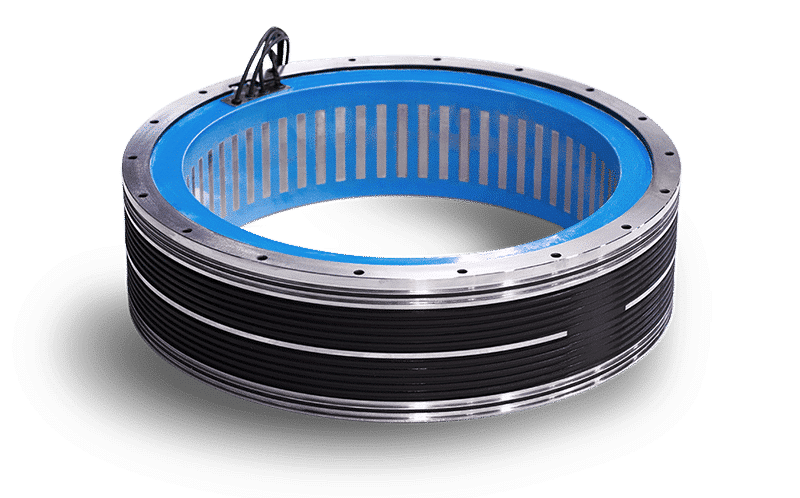

Direct Drive Motors are particulary advantageous in frameless configuration, as they eliminate frame, and housing.

Frameless design results in a more compact and lightweight motion solution, reducing noise, vibrations, maintenance, costs and overall complexity.

The absence of an housing frame facilitates better integration, scalability, and easier installation and inspection.

As explained, frameless configuration does not require housing frame: the motor consists only of the rotor with permanent magnets and the stator with windings producing the electromagnetic field.

Windings can also be customized with customer preferences or specific design demands.

Torque and Spindle Motors, High torque electric motor, High torque servo motor, High torque low rpm electric motor, Low speed high torque electric motor, High torque low rpm ac electric motor, Small high torque electric motor, High torque brushless electric motor, High torque low rpm motor, High torque low rpm electric motor, High torque low rpm ac electric motor, Compact High torque electric motor, Ultra high torque motor, High torque dc motor, 12v dc motor high torque, 12 volt dc motor high torque, 12v dc motor high torque low rpm, 24v dc motor high torque high speed …