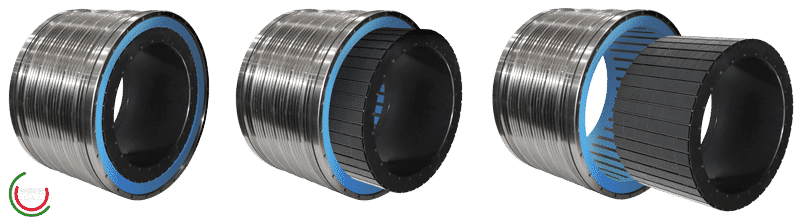

Designed for outstanding performance in torque density, low to medium speed, and rapid positioning. Equipped with cutting-edge technology like an innovative electromagnetic circuit and magnet dovetail positive locking, the TKH Torque Motors Series excels in demanding applications needing both slow and fast positioning. Accurate magnetic circuit design and strict manufacturing tolerances guarantee minimal cogging ripple and smooth torque delivery.

KEY PERFORMANCE AND RANGE

The TKH series is entirely made in Italy with a local supply chain, ensuring a shorter, more reliable supply chain, increased flexibility, and faster response times.

Highly modular design ensures quicker availability of parts, minimizing the risk of stock shortages and downtime.

TKH “frameless” motors are engineered for demanding applications, designed to seamlessly integrate into equipment with a robust construction, including a three-phase stator encapsulated in epoxy and rare earth magnets. These motors prioritize performance, efficiency, and compactness, achieved through novel magnetic design and high-density winding.

Engineered for compact size, high efficiency, and reliability.

Utilizes advanced encapsulant with superior thermal properties.

Features surge-hardened Class H insulation for high DC voltages.

Rigorously tested for safety and performance.

Equipped with winding star point and insulated power leads for enhanced reliability.

Employs isotropic, surface magnet type permanent magnet rotors for reduced cogging.

Utilizes coated high-temperature magnets for stability.

Rotor-to-machine interface optimized for high peripheral speeds.

Incorporates a specialized cooling circuit for efficient heat exchange and uniform temperature control.

Offers options for water-glycol or oil cooling, with precautions against corrosion.

Equipped with O-rings and leakage collection ring for reliable sealing and protection.

Standard frames are machined from C50 steel for corrosion resistance and improved performance.

All motors come with 1m power and sensor cables for easy integration. Oil cooling, although less thermally efficient, offers good dielectric properties and leak protection for specialized applications, with derating and custom specifications as necessary.

Assembly of the rotor into the stator requires special care due to magnetic forces and high voltage generation, detailed in the user manual for safe operation.

Varied diameters, stack lengths, and windings in TKH electric motors cater to specific requirements. Special configurations are available but may take longer for delivery. TKH motors come as separate stator and rotor units, with pre-assembled units available upon request.

It’s important to ensure that the correct code is used in order to receive the correct motor specifications and configurations for your application.

TKH Motors provides diverse torque and diameter options to suit different application requirements.

Here are the available options:

• Outside diameters range from 230 to 1020 mm.

• Stack length modules come in finite steps from 50 to 200 mm.

• Winding configurations are tailored for varying torque constants.

• Custom stack lengths and windings are available upon request.

support@phase.eu for technical support

repair@phase.eu for failure analysis and repair activities

customercare@phase.eu for any enquiry and customer assistance